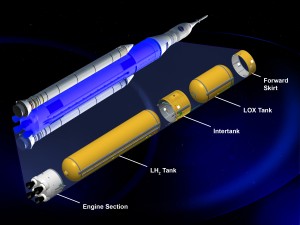

How do you get into deep space? With a lot of rocket propellant. That’s why the nation’s new rocket that NASA is building will have tanks in its core stage that hold 733,000 gallons of propellant!

Testing the liquid hydrogen and liquid oxygen tanks for Space Launch System (SLS) requires serious structures. NASA is building a test stand for each of the two tanks, and the major construction on the test structure for the bigger tank has just been completed. The larger of the two tanks will hold 537,000 gallons of super-cooled liquid hydrogen inside the rocket’s core stage.

SLS liquid hydrogen tank test stand. Image credits: NASA/MSFC/Emmett Given

At NASA’s Marshall Space Flight Center, the carefully-constructed structural test stand for the tank is 221 feet tall. Watch a time-lapse of the structure being built here.

Expanded view of SLS core stage. Image Credit: NASA/MSFC/Kevin Obrien

Currently, Marshall engineers are installing equipment needed for testing after the stand was handed over from contractors and steelworkers in December, including a complex network of cables, pipes, valves, control systems, cameras, lighting and specially designed test equipment. The manager for SLS structural strength testing at Marshall, Robert Bobo, recently remarked on the pride of the people working on the test stand and how widespread they are across the country.

So what exactly will the test stand do? By pushing, pulling and bending the liquid hydrogen qualification test article, it will simulate launch and flight dynamics. This qualification test article was made by a founding member of the Coalition, Boeing, at NASA’s Michoud Assembly Facility in New Orleans. The test article is 149 feet long and consists of a liquid hydrogen tank and equipment attached to both ends that simulate other parts of the rocket’s 212-foot core stage.

When testing starts on the test article after it arrives at Marshall, it will be suspended under a crosshead between the two towers. Thirty-eight hydraulic cylinders will then be calibrated individually. They’ll be outfitted with custom-built test cells that will send and receive instructions and data. Next, the cylinders, weighing between 500 and 3,200 pounds each, will be positioned at specific points along the whole tank. The base of the tank will have 24 of the biggest cylinders simulating thrust produced by four engines at the bottom of the core stage.

The hydraulic cylinders will extend and retract, push and pull in different configurations against the test article, test stand base and towers. They’ll apply millions of pounds of pulling and crushing force. They’ll also apply up to 340,000 pounds of sideways or shearing force.

Thirty or more test scenarios will be performed. During each of them, instrumentation will capture strain and detection measurements, temperatures, pressures, high-definition images, and more.

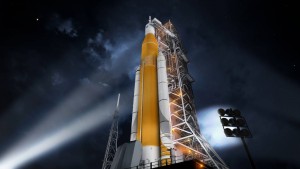

Artist’s concept of SLS Block 1. Image credit: NASA/MSFC

The other tank inside the core stage of the rocket will hold 196,000 gallons of super-cooled liquid oxygen. The test stand that will evaluate the liquid oxygen tank test article is being worked on nearby.

The propellants from each of these tanks will power the four engines on the bottom of the rocket’s core stage. These are the RS-25 engines – enhanced versions of the highly reliable space shuttle main engines. Together, the liquid hydrogen and liquid oxygen tanks will hold 733,000 gallons of rocket fuel enabling the engines to produce 2 million pounds of thrust.

SLS will embark on its first mission in 2018 when it carries the Orion crew vehicle. SLS is designed to evolve into more powerful configurations to support future missions into deep space. Overall, the first configuration of SLS will provide 8.8 million pounds of thrust – that’s 15 percent more thrust than the Saturn V rocket had at launch.

Learn more about nation’s new rocket at NASA.gov.