Orion

Orion is designed for long-term human deep space exploration. CDSE member Lockheed Martin is the prime contractor for the development and production of the Orion spacecraft. The company works with international partners to build Orion. Airbus, on behalf of ESA, works on the design and development of Orion’s European Service Module (ESM). Coalition member Aerojet Rocketdyne also has a key role in Orion.

The company provides the primary propulsion for the spacecraft’s major maneuvers with an engine mounted on top of the spacecraft’s ESM and produces the auxiliary engines used to maintain Orion’s trajectory and position. Aerojet also builds the spacecraft’s Launch Abort System jettison motor, and provides the Reaction Control System and pressure vessels that help with reentry and splashdown. CDSE member Northrop Grumman manufactures the main abort motor and attitude control motor for Orion.

Orion’s Ascent Abort-2 test, July 2019. Credit: NASA/Rad Sinyak

Space Launch System (SLS)

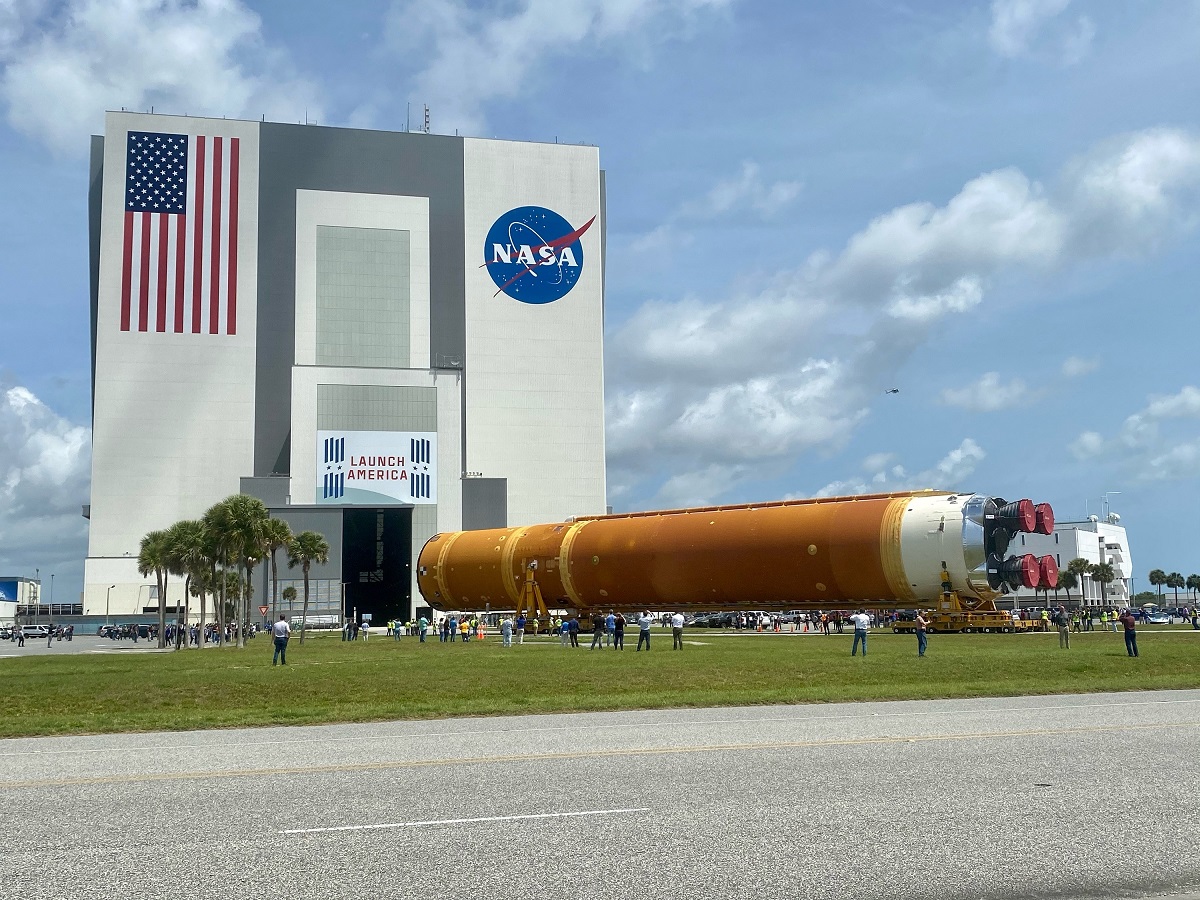

The SLS is the most powerful rocket NASA has ever built, and can support launching Orion, astronauts, and large cargo to deep space on a single mission without the need to conduct orbital refueling to resume exploration. Its solid rocket boosters are the largest ever built for flight. The rocket uses a core stage with four RS-25 engines, which have been enhanced since their use as the main engines for the Space Shuttle.

The Artemis I SLS core stage as it enters the Vehicle Assembly Building at NASA’s Kennedy Space Center after successfully completing a Green Run test campaign at the Stennis Space Center. At KSC the core stage will be mated to the rest of the components for the Artemis I mission. Credit: NASA

Coalition member Boeing is the prime contractor for the design, development, test, and production of the Space Launch System. Northrop Grumman manufactures the five-segment solid rocket boosters for the SLS. Aerojet Rocketdyne is the prime contractor for the RS-25 engines that will be used to propel SLS. Aerojet Rocketdyne’s RL10B-2 engines will power the upper stage (Interim Cryogenic Propulsion Stage) of the SLS, which in turn is manufactured by CDSE member United Launch Alliance (ULA). Later iterations of the SLS will utilize the “Exploration Upper Stage” that the United States that provide tools, software, testing, and logistics in the production of the SLS, and many of which are CDSE members.

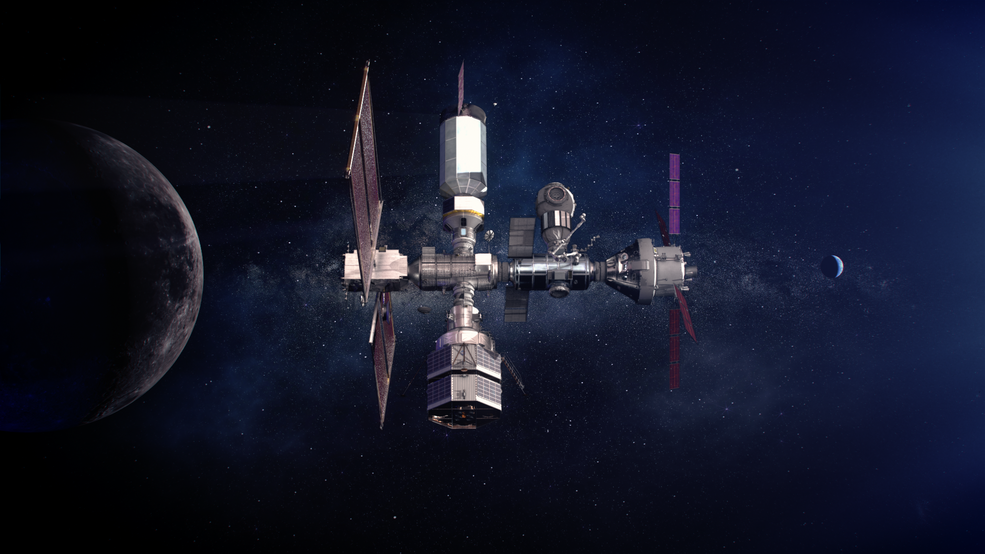

Gateway

The Gateway will be a small, movable space station located in lunar orbit. It will help to establish a sustainable presence on the Moon by providing living quarters, serve as a place for research, and offer docking ports for visiting spacecraft. The Gateway will also serve as a communications relay and can serve as a prototype for a Mars transit vehicle. By providing a permanent outpost near the Moon, the Gateway offers a platform for continued international cooperation in science, exploration, and the eventual economic development of cislunar space.

Gateway rendering. Credit: NASA

NASA’s deployment of Gateway in lunar orbit is based on a phased approach. By the time of the Artemis III mission, there will be a simplified version of the Gateway consisting of a Power and Propulsion Element (PPE) and a Habitation and Logistics Outpost (HALO) mini-habitation module. NASA selected CDSE member Maxar Technologies to build the Power and Propulsion Element, a 50-kilowatt solar electric propulsion spacecraft. Meanwhile, CDSE member Northrop Grumman was selected by NASA to provide the HALO module.

As the Moon exploration program reaches missions beyond Artemis III, NASA will lead expansion of the Gateway in lunar orbit. This will be done in concert with international partners, who are already taking steps toward development.

Exploration Ground Systems

CDSE member Jacobs is the operations support contractor for the NASA Exploration Ground Systems (EGS) program at Kennedy Space Center. EGS manages systems and facilities necessary to build and operate rockets and spacecraft during assembly, transport, launch, and reentry. EGS is helping to build infrastructure that supports different spacecraft, such as both the SLS and Orion.

Mobile launcher and crawler-transporter 2 (CT-2) at NASA’s Kennedy Space Center in Florida. Credit: NASA/Kim Shiflett

The EGS program has also brought about the ability to make infrastructure available to both government and commercial clients. This approach contributes to affordability by distributing costs among multiple users. Jacobs’ work includes upgrading Launch Pad 39B, the crawler-transporters, the Vehicle Assembly Building (VAB), the Launch Control Center’s Young-Crippen Firing Room 1, the mobile launcher (ML), and more.

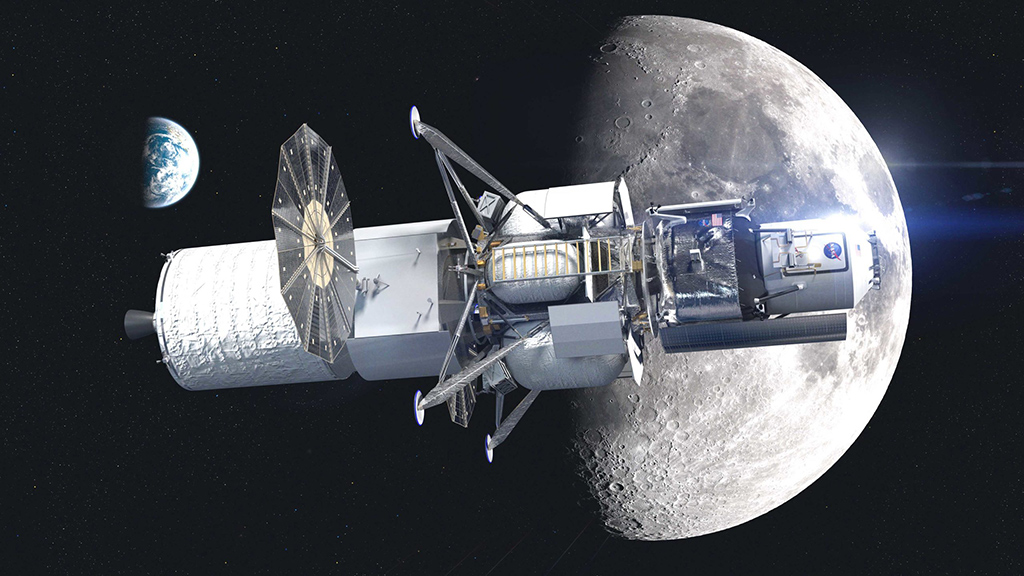

Landers

National Team human lunar lander. Credit: Blue Origin

NASA is working with industry to develop human landing systems (HLS) through the Next Space Technologies for Exploration Partnerships (NextSTEP) public-private partnership model. The HLS program is tasked with developing the lander that will bring two astronauts from the Gateway to the Moon’s south pole under the Artemis program. NASA selected the company SpaceX to develop the HLS for the initial mission of the program. The agency has stated it will work with other companies to develop landers for future Artemis missions.