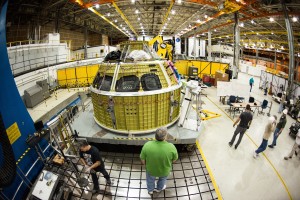

NASA’s replacement for the Space Shuttle is one step closer to getting off the ground as the space agency announced last week it had completed welding the main structure for the Orion spacecraft.

Together with the Space Launch System (SLS), which is also currently being developed, Orion is expected to take humans to Mars – and possibly beyond.

“We’ve started off the year with an key step in our process to get ready for Exploration Mission-1, when together Orion and SLS will travel farther than a spacecraft built for humans has ever traveled,” Mike Sarafin, NASA’s Exploration Mission-1 manager, said in a statement. “This brings us closer to our goal of testing our deep space exploration systems in the proving ground of lunar space before we begin sending astronauts days to weeks from Earth.”

The welding Orion’s seven large aluminum parts, which started in September 2015 at the Michoud facility in New Orleans, was a painstaking process. Engineers prepared and equipped each component with stress gauges and wiring to observe the metal during the welding. The pieces were linked using a cutting-edge course of action known as friction-stir welding, which generates incredibly strong bonds by altering metals from a solid into a plastic-like state, and then utilizing a revolving pin tool to soften, mix and forge a connection between two metal parts to create a uniform welded joint. The result is a vital feature of next-generation space hardware, NASA said.

Read more at RedOrbit.