An important part of preparing for the first flight of a new launch vehicle is to make sure components are able to handle structural loads. At NASA’s Marshall Space Flight Center in Huntsville, Alabama, construction is underway to prepare for just that.

New test structures are now being constructed to evaluate components of NASA’s new advanced launch vehicle, the Space Launch System (SLS). The testing that will take place at Marshall’s Structural and Environmental Test Laboratory will be an exciting next step toward the first flight of the SLS. NASA has built spacecraft components at this facility for decades.

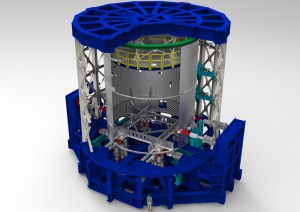

The parts of SLS that will be tested at this facility are the core stage intertank and engine section. The core stage of the SLS will store the fuel for the engines – cryogenic liquid hydrogen and liquid oxygen. The prime contractor for the core stage is The Boeing Company.

The core stage intertank is the component that connects the liquid hydrogen and liquid oxygen tanks. It is also where the rocket’s two, five-segment solid rocket boosters will be attached. The engine section structure is also part of the core stage, and houses the engines. The SLS core stage will be powered by four RS-25 engines which are built by Aerojet Rocketdyne of Sacramento, CA. The RS-25 is the world’s most reliable rocket booster engine.

The core stage intertank will have test loads applied to it by hydraulic cylinders, some cylinders weighing more than a car. The tests will be to simulate structural load conditions of prelaunch, launch and spaceflight. Hydraulic cylinders will push, pull, twist and bend the intertank and engine section qualification test articles.

Panels for the intertank main tower have been installed in the load test annex. These twelve, 55-foot panels were built by Weldall Manufacturing Inc. Four additional tower structures will delivered and installed as one of the next steps. These structures are being manufactured by Steward Machine Co. and will be followed in late April by other structures from Weldall. The upcoming delivery from Weldall will be of the base frame for the engine section test structure.

“It’s exciting to be a part of the future of human spaceflight,” said Tim Flores, integration manager for the SLS Stages Office at Marshall. “Testing this hardware is a major stepping stone before the first flight of SLS.”

To learn more about the SLS core stage, check out http://www.nasa.gov/sites/default/files/atoms/files/sls_core_stage_fact_sheet_01072016.pdf

To learn more about SLS, visit https://www.nasa.gov/exploration/systems/sls/overview.html