December was a busy month for America’s new rocket that will take humans into deep space. NASA’s Space Launch System, or SLS, made massive headway toward its first launch.

SLS will head off toward deep space for the first time in 2018. On its inaugural flight, the rocket will be carrying NASA’s new crew vehicle, Orion, and thirteen smaller satellites known as CubeSats.

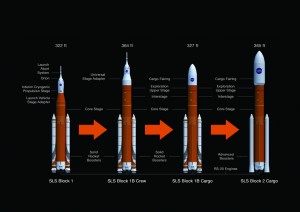

NASA isn’t only working on this first flight of SLS; they’re also performing wind tunnel tests for the next and more powerful configuration of SLS. Take a look at the rocket’s evolution into its future configurations:

Image credit: NASA/MSFC

Supersonic wind tunnel testing is essential in understanding how the rocket will travel through Earth’s atmosphere. Engineers last month were evaluating the next version of SLS in order to refine its design, and tests will continue this year.

Image credits: NASA/Ames/Dominic Hart

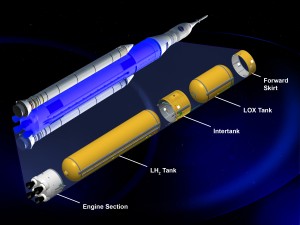

Once in space, what will push the Orion spacecraft on its mission beyond the moon before it returns to Earth? That would be the interim cryogenic propulsion stage, or ICPS. A liquid oxygen and liquid hydrogen based system, the ICPS was designed by Boeing, a Coalition founding member. In December, the propulsion system for the ICPS completed major assembly in Alabama, another big step forward in advance of the 2018 launch.

Image credit: ULA

In December, another founding member of the Coalition, Orbital ATK, applied paint to a part of the rocket’s solid rocket boosters called the aft skirt. This aft skirt came from the space shuttle era and following inspection and being resurfaced, was primed and painted. There will be two boosters on the 2018 flight, each providing 3.6 million pounds of thrust!

Early in December, suppliers in Texas received appreciation for all of their hard work contributing to both SLS and Orion. In Texas alone, more than 100 companies are helping build the nation’s new rocket and deep space crew vehicle. One of them, Houston Precision Fasteners, provides SLS with essential fasteners that are used throughout its booster motor. Most of the fasteners made by the company, a Coalition member, are used on the forward skirt assembly.

Speaking of the forward skirt, the welding on this component of SLS was completed last month. The forward skirt will hold some very important parts of the rocket – its flight computers, cameras and avionics. The forward skirt is part of the rocket’s core stage.

Image credits: NASA/MSFC/Kevin Obrien

A robot was also prepared by a team last month for friction plug welding of the rocket’s giant liquid hydrogen tank. At NASA’s Michoud Assembly Facility in New Orleans, the technique will be used to fill holes left in the tank after being assembled in a bigger robotic welder – an essential part of manufacturing. At more than 130 feet long, the liquid hydrogen tank is the largest part of the core stage.

Progress continues this month on the nation’s new rocket, with each month bringing it a step closer toward its first launch in 2018. Space Launch System is designed to enable a new era of exploration beyond Earth’s orbit, and will have the capability to launch humans on missions to multiple destinations in deep space aboard the Orion spacecraft. With the ongoing momentum toward the rocket’s first launch combined with individuals contributing to the rocket from many parts of the country, SLS will usher in a new and exciting era of deep space exploration.

Learn more about SLS at NASA.gov.